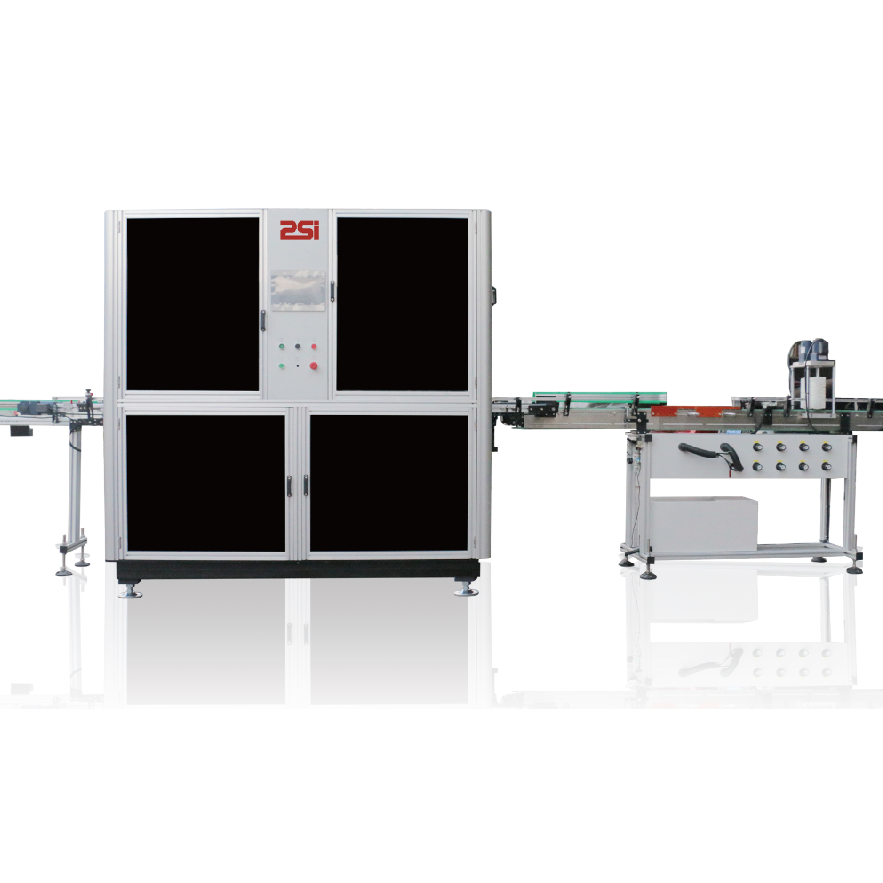

GH2 Automatic Heat Transfer Machine

Description:

- Automatic system with all servo driven: heating roller up/down, left/right, jigs rotation, all driven by servo motors

- Quick and easy change over from one product to another

- PLC control & touch screen operation system

- Safety operation with CE

- Also suitable for hot stamping after bottles printed with primer

- Camera vision system for pre-registration optional

- Overview

- Related Products

Why Heat Transfer? Compare to Screen and Hot Stamp.

- Multi colors in single press.

- High accuracy with tolerance max +/- 0.1mm - No pre-treatment required.

- Perfect adhesion on glass.

- Hybrid process combing screen printing + hot stamping allowing lower cost.

- Green technology. No solvent, no ink, no bad smell.

- Higher production time and improvement of rejection rate.

- Quick set up time, fast change over.

- Less operators, less skill requirement.

Application:

Heat transfer on cylindrical / oval / square glass bottles.

Tech-data:

|

Parameter / Model |

GH2 |

|

Max Printing Speed |

30 – 40 pcs/min |

|

Printing Diameter |

25 – 100 mm |

|

Product Height |

50 – 350 mm |

|

Roller Length |

220 mm |

|

Power |

380V AC, 3Phases, 50/60 Hz |

|

Air Consumption |

5 - 7 bars |

EN

EN

AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES IW

IW ID

ID VI

VI TH

TH TR

TR FA

FA